Bioreactors¶

Why the dinosaurs died out is not known, but it is supposed to be because they had minute brains and devoted themselves to the growth of weapons of offense in the shape of numerous horns.

—Bertrand Russell

We have examined a number of conservation and rate equations that are applicable to all Chemical and Biological Engineering processes. However, it is useful to examine some processes specifically biological in nature.

We could cover biological heat transfer, biological mass transfer, biological reactors, etc.

Here we will focus on biological reactors, i.e., bioreactors.

What is a bioreactor¶

An apparatus for growing organisms (yeast, bacteria, or animal cells) under controlled conditions. Used in industrial processes to produce pharmaceuticals, vaccines, or antibodies. Also used to convert raw materials into useful byproducts such as in the bioconversion of corn into ethanol.

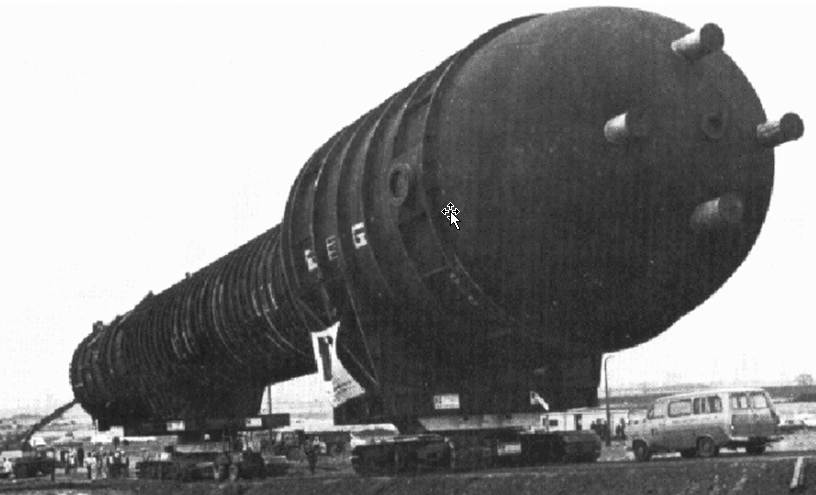

Industrial bioreactor¶

World’s largest industrial fermenter (as of 1978)¶

The fermenter is 200 feet high and 25 feet in diameter

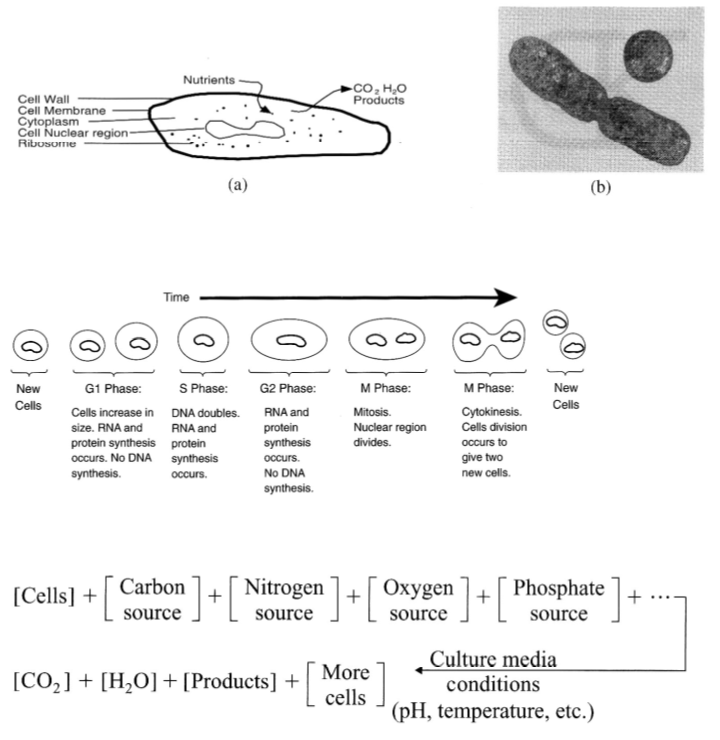

Bioreactor basics¶

More about bioreactors:

They are systems or devices that supports a biologically active environment

They are vessels in which a chemical process is carried out which involves organisms or biochemically active substances derived from such organisms

They can be either aerobic or anaerobic

They are commonly cylindrical, ranging in size from liters to cubic meters, and are often made of stainless steel

They supply a homogeneous (same throughout) environment by constantly stirring the contents.

They give the cells a controlled environment by ensuring the same temperature, pH, and oxygen levels.

Important biological issues¶

Limiting substrate: The substrate or substrate(s) (energy source, carbon source and/or nutrient source) which is/are first exhausted in batch growth. This substrate(s) has a direct influence on the kinetics of cell growth.

In excess: The substrate or substrate(s) (energy source, carbon source and/or nutrient source) which is/are not exhausted at the end of batch growth. This substrate(s) has no effect on the kinetics of cell growth.

Exercise: Cell numbers versus time in a bioreactor

Considering the above factors, make a sketch of the number of cells over time in a bioreactor.

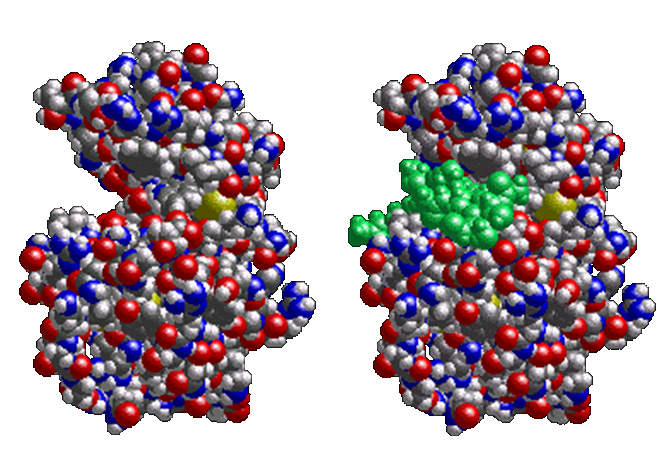

Quantifying reactions rates for enzymes¶

Maud Menten and Leonor Michaelis

Michaelis-Menten kinetics

where, \(v_{0}\) is the initial ‘reaction velocity’, \(r_{p}\) is the rate of production of the product, \(r_{s}\) is the rate of production of the substrate, \(S\) is substrate, \(P\) is product, and square brackets ( \([\ ]\) ) represent concentration.

This equation governs the initial reaction rates (i.e., not including the reversion of products).

Exercise: Michaelis-Menten kinetics

Consider the Michaelis-Menten equation.

What are the units of \(V_{\max}\) and \(K_{m}\)?

Sketch out the rate of product formation as a function of substrate concentration.

What is the order of the reaction at ‘relatively low’ and ‘relatively high’ substrate concentrations?

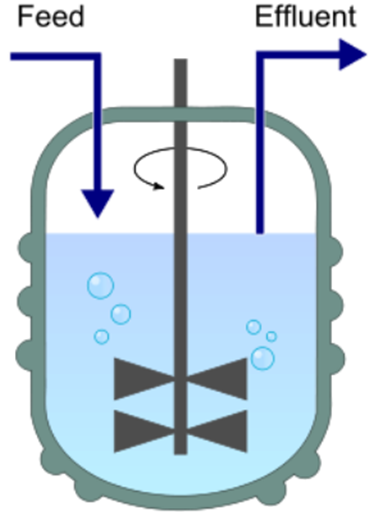

Reactor types¶

Chemostat (chemical environment is static)

A bioreactor to which fresh medium is continuously added, while culture liquid is continuously removed to keep the culture volume constant

What type of reactor is this?

Let’s compare the nomenclature of chemical reactors (CSTRs) with that for bioreactors and show some typical units:

Chemical reactor |

Bioreactor |

|---|---|

concentration: \(C\) [\(\si{gmol/L}\)] |

biomass: \(x\) [\(\si{g/L}\)] |

volume: \(V\) [\(\si{L}\)] |

volume: \(V\) [\(\si{L}\)] |

volumetric flowrate: \(\dot V\) [\(\si{L/s}\)] |

volumetric flowrate: \(F\) [\(\si{L/s}\)] |

residence time: \(\tau=V/\dot V\) [\(\si{s}\)] |

dilution rate: \(D=F/V\) [\(\si{1/s}\)] |

reaction rate constant: \(k\) [\(\si{1/s}\)] |

biomass growth rate: \(\mu\) [\(\si{1/s}\)] |

reaction rate (example reaction rate equation): \(r_{rxn} = k\ C_{A}\) [\(\si{gmol/L\cdot s}\)] |

cell growth rate (example growth rate equation): \(r_{x} = \mu \ x\) [\(\si{g/(L \cdot s)}\)] |

As for chemical reactors, we can construct our general material balance:

Rate that Rate that Rate that Rate that

biomass enters + biomass is formed = biomass leaves + biomass is consumed

the system in the system the system in the system

It is generally assumed that the biomass is not consumed in a bioreactor. With that in mind, we can use the appropriate symbols and relationships to arrive at the mathematical form of the material balance:

With a sterile feed (no biomass in), and recalling that for a well mixed reactor \(x_{out}=x\) , we have

Substituting in the expression for the growth and rearranging gives

Exercise: Chemostat analysis

Questions:

What is the relationship between the dilution rate, \(D\), and growth rate, \(\mu\) , at steady state?

What happens if \(D\) is very large?

Considerations in bioreactor design¶

The design of a bioreactor can be different from that of a chemical reactor in many ways.

Exercise: Bioreactor features

What are some of the issues that must be considered to assure the health and productivity of microorganisms?

Based on part 1, make a list of the features that make a bioreactor different from a standard chemical reactor.

Based on part 2, sketch a bioreactor and include all of the equipment that you think is necessary.