Research

In our research group we are focused on developing novel multifunctional polymers and composite materials that exhibit revolutionary manufacturability, performance, and longevity. We use a judicious combination of material and engineering design, functional constituents, and manufacturing strategies to develop new solutions to current engineering challenges while considering the fundamental characteristics of the target system from design and manufacturing to operational conditions. As a result, our research is highly interdisciplinary and spans several engineering and scientific disciplines including advanced manufacturing, materials science, mechanics, and chemistry.

Net-zero energy manufacturing of polymers and composites via frontal polymerization

The superior thermochemical stability and mechanical performance of thermoset polymers and their composites has facilitated widespread adoption of these materials in aerospace, automotive, marine, and energy sectors. The curing process of thermosets often requires heating the resin for several hours at elevated temperatures (ca. 180 °C) in large ovens or autoclaves, leading to high cost of manufacturing in terms of time, energy, and resources. We have recently demonstrated a novel curing strategy based on “frontal polymerization” (FP) to rapidly manufacture high-performance thermoset and composite parts with minimal energy input. FP is an exothermic reaction wave that provides the energy for materials synthesis, rather than requiring external energy. Applying a localized thermal stimulus on the reactive monomer solution triggers the polymerization, which proceeds in an autoactivating fashion without requiring any further external energy. Using this curing strategy, we can reduce the manufacturing energy of large parts by 10 orders of magnitude and manufacturing time by 2 orders of magnitude.

Ref.: Nature

3D printing of polymers and composites

Although 3D printing has revolutionized the manufacture of 3D objects, the quality of resulting products is not yet comparable to conventional manufacturing methods due to the underlying layer-by-layer printing and rapid phase-transformation processes. Therefore, there is still a need for developing new materials and processing conditions specifically tailored for 3D printing of high-quality parts. In our group, we explore both thermoset and thermoplastic polymers in order to develop new printing techniques and materials. We investigate various aspects of 3D printing from fundamental understanding of the physiochemical phenomena that occur during and after printing to final characterization of printed materials and structures.

Ref.: Nature

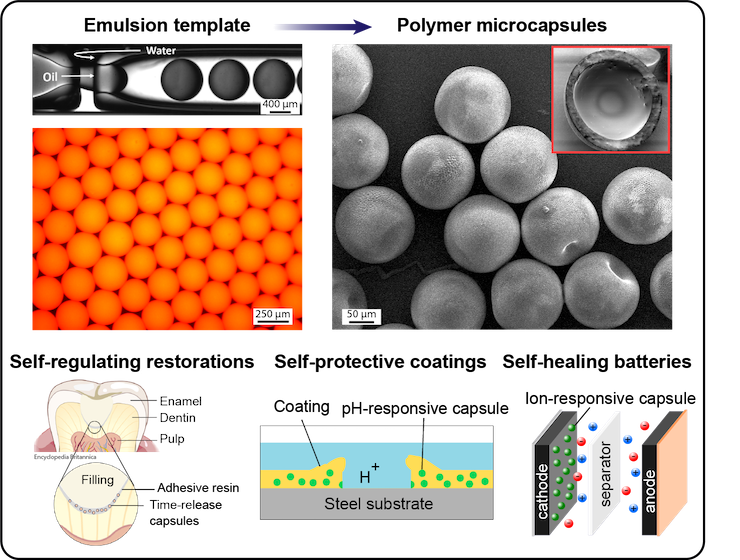

Self-regulating materials

Functional integrity of synthetic materials can be compromised by various operational and environmental stresses which if not properly controlled may eventually lead to the failure of a system (e.g. damage or defects in coatings can lead to catastrophic corrosion failure). Biological systems are similarly susceptible to external stresses but instead use intriguing auto-regulatory mechanisms to maintain or recover their functions and avoid large-scale failures. How can we create synthetic material systems that are able to protect themselves like biological systems and exhibit expanded life cycle and reliability? Exploiting functional materials through a well-designed architecture offers unique opportunities for introducing bioinspired functions to synthetic materials for enhanced performance and life cycle. One approach is to develop autonomous material systems that contain stimuli-responsive polymer microcapsules for controlled, “on demand” delivery of active agents to enable self-healing or self-regulating capabilities in a variety of materials.

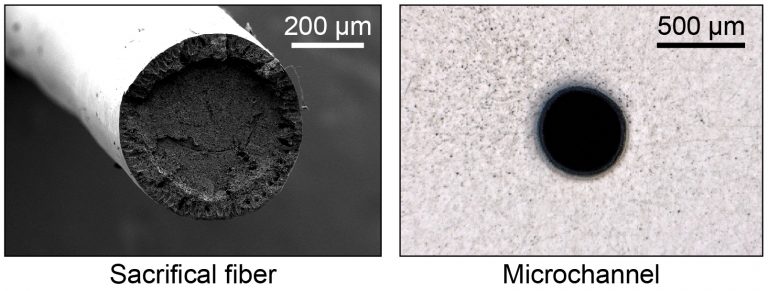

Vascular materials and structures

Biological systems use complex circulatory networks for the continuous transport of fluids in order to perform several functions such as homeostasis, healing, nutrient transport, etc. Mimicking biological circulatory systems, creation of vascular networks in structural or coating materials enables novel functional capabilities such as self-healing and thermal regulation, which can result in dramatic improvement in the reliability, performance, and design simplicity of large engineering systems. In our group, we look into different methods for the creation of vascular materials as well as the introduction of active functionalities in structural and engineering materials.

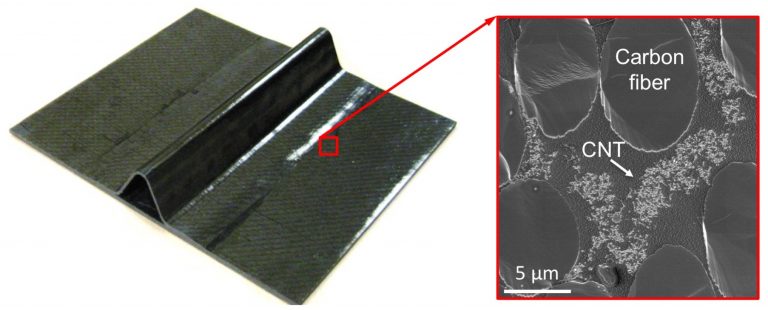

polymer nanocomposites

The addition of nanoparticles with unique geometrical and functional properties into polymers allows for creating polymer nanocomposites with synergistic multifunctional properties, unachievable with a single material design. For example, very low concentrations of conductive nanoparticles such as carbon nanotubes makes the electrically-insulating polymers conductive while maintaining or improving other intrinsic properties of the host polymer. Given the high number density of nanoparticles and their nanoscale dimension, the efficient fabrication of polymer nanocomposites is however arduous and requires precise selection of processing methods and chemical functionalization approaches. We use various types of nanoparticles to add new functions (e.g. stimuli-responsiveness, mechanical reinforcement, barrier properties, electrical conductivity, electromagnetic shielding, etc.) to host polymer materials. We also use nano-modified polymers in fiber-reinforced composite materials in order to create multifunctional, multiscale composites.