Our Mission

Colorado State’s Industrial Assessment Center (CSU IAC) program provides eligible small and medium-sized manufacturers with comprehensive on-site industrial assessments by CSU engineering students to determine resource and cost savings, and is performed at no cost to the manufacturer.

An industrial assessment involves an on-site visit and in-depth review of a plant site, including its facilities, services, and manufacturing operations. The FREE assessment involves a thorough examination of potential savings from:

- Recommendations for improved energy efficient operations.

- Ideas for waste minimization and productivity improvement.

- A written report that describes these recommendations.

The assessment begins with the CSU IAC team conducting a preliminary survey, followed by a one or two day site visit, taking engineering measurements as a basis for assessment recommendations. In follow-up the team performs a detailed analysis for specific recommendations having estimates of costs, performance, implementation costs, and payback times.

Within 60 days, a confidential report that details the analysis, findings, and recommendations of the team is sent to the plant. Six to nine months later a follow-up Implementation Survey is taken by e-mail and/or phone calls to the plant manager to verify which recommendations will be implemented within a 2 year time frame. Previous data show that around 50% of recommendations are successfully implemented.

The CSU IAC and its predecessor programs (the Energy Analysis and Diagnostic Center and the Waste Minimization Assessment Center) have been providing plant assessments and recommendations for plant improvement since 1984 to over 560 manufacturing plants.

Contact the center

Center Director: John Mizia

Email: john.mizia@ColoState.Edu

Phone: 970-491-4767

Mailing Address:

Department of Mechanical Engineering

1374 Campus Delivery

Fort Collins, CO 80523

Eligibility

Companies eligible for FREE energy efficiency, pollution prevention, and productivity improvement assessments must be manufacturers (SIC Code 2000-3999). In addition, any three of the following criteria must be met:

- Have $100,000/yr to $2.0 million/yr in total energy costs

- Have a maximum of 500 employees

- Have a maximum of $100 million/yr gross annual sales

- Lack in-house professional expertise in energy use and conservation.

- Must be a US Manufacturer

- Within 150 miles of an IAC

Overall IAC program

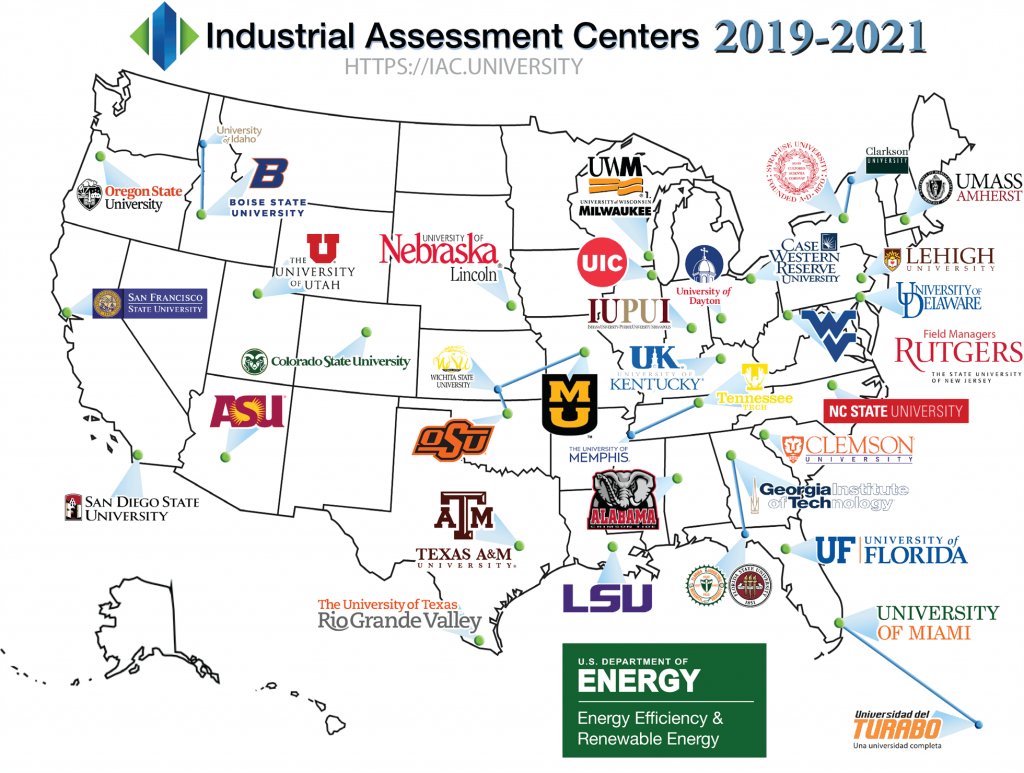

The U.S. Department of Energy sponsors 31 Industrial Assessment Centers across the United States – each monitoring and helping clients across their general areas. The program was originally founded in 1976 by the Department of Commerce in response to the oil embargo as well as rising energy costs across the nation. It was shifted to the Department of Energy in 1978. The IAC at ASU has been renewed through 2021, alongside the 30 other centers.

IAC’s across the United States have trained over 3500 engineering students and have performed over 17,000 assessments with more than 133,000 associated recommendations. The average recommended yearly savings is $136,086.