Composite Design and Fabrication

Many projects related to design and fabrication of composites have been undertaken at the Composite Materials, Manufacture and Structures Laboratory. These projects have ranged from the composites hardware for student design competition projects, such as Solar Car, Formula SAE and Walking Machine, to redesigns of industrial equipment.

Formula Car Chassis

CMMS has supported the development of composite monocoque chassis’ for the undegraduate Formula SAE Team at Colorado State University since the Team first competed in 1996. Student generated tooling and mold design has led to 2 full generations of monocoques. In each case the chassis has been primarily carbon fiber reinforced epoxy, and has varied between wet layup with cloth and prepreg lamination over the years.

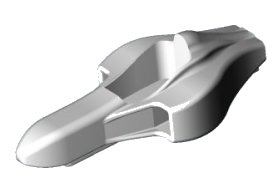

Within the new Performance Engineering Program, graduate researchers have been involved in helping generate the 3rd generation Formula SAE chassis. This monocoque design is far more ambitious than the past generations, with multiple molded shells being assembled to generate a complex chassis geometry. This bonded multi-shell approach is based on previos CMMS research on multi-shell pressure vessels. The design of the multi-shell monocoque is reported on in a Conference article at the SAE Motorsport Engineering Conference in December 2002. This chassis incorporates composite crush structures for driver safety, a fully enclosed powertrain, and ultimately full aerodynamic features.

Multi-Shell Pressure Vessel —- Multi-Shell Chassis Concept —- Assembled Composite Chassis Concept with Fairings

Solar Car

These vehicles used composites for primary structure and suspension systems to attain the necessary light weight and high strength. All tooling development and fabrication was performed in the Laboratory. The cars were fabricated from a combination of carbon fiber and Kevlar fiber reinforcements. In addition to vacuum bag, wet layup processing for large parts, components such as steering tie rods have been produced by filament winding and other suspension components by autoclave cure. Two vehicles were raced in National competitions, the first from Orlando to Detroit in the 1990 GM Sunrayce USA and again in 1993 in the Sunrayce from Arlington, TX to Minneapolis. In addition, the first race vehicle was invited to Japan to compete. These have been primarily Undergraduate Educational projects.

Industrial Redesign for Composites

Commercial Stainless Steel Pressure Vessel ——– Multi-Shell Concept ——– Composite Hydroburst Test Specimens

Related Publications

Journal Articles

- Weidner, L.R., Radford, D.W., and Fitzhorn, P.A., “A Multi-Shell Assembly Approach Applied to Monocoque Chassis Design”, SAE 2002 Transactions, Journal of Passenger Cars – Mechanical Systems, 2003, p.2486.

- Radford, D.W., Scott, E., and Fitzhorn, P.A., “A Liftless Electronic 100ms Shift System For Motorcycle-Engined Racecars”, SAE Transactions, Journal of Engines, 2003, p.2796.

- Radford, D.W. and Goetschel, D.B., “Multi-Shell Composite Pressure Vessel Development”, Journal of Advanced Materials, Vol. 28, No.4, July 1997, pp.8-19.

Conference Proceedings

- Radford, D.W. P.C. Fuqua, and L.R. Weidner, “Tooling Development for a Multi-Shell Monocoque Chassis Design”, 36th International SAMPE Technical Conference, SanDiego, CA, Nov. 15 – 18, 2004.

- VanGoethem, D. and Radford, D.W., “Design of Structually Coupled Composite Beams Under Combined Bending and Tension Loading”, 36th International SAMPE Technical Conference, SanDiego, CA, Nov. 15 – 18, 2004.

- Weidner, L.R., Radford, D.W., and Fitzhorn, P.A., “A Multi-Shell Assembly Approach Applied to Monocoque Chassis Design”, Paper #2002-01-3360, SAE Motorsports Engineering Conference, Indianapolis, IN, December 2 – 5, 2002.

- Radford, D.W., Scott, E., and Fitzhorn, P.A., “A Liftless Electronic 100ms Shift System For Motorcycle-Engined Racecars”, Paper #2002-01-3322, SAE Motorsports Engineering Conference, Indianapolis, IN, December 2 – 5, 2002.

- VanGoethem, D.J. and Radford, D.W., “A Sub-Scale Flexure Test for High Modulus Composites”, 31st International SAMPE Technical Conference, Chicago, IL, Oct. 26 – 30, 1999.

- Radford, D.W. and Carlson, E.D., “Bonded, Multi-Shell Composite Pressure Vessel Development”, 28th International SAMPE Technical Conference, Seattle, WA, Nov. 4 – 7, 1996.

- Radford, D.W., “Modern Trends in Fiberglass Composite Design”, Presented at the SAE International Truck & Bus Meeting and Exposition, Winston-Salem, NC, November 14, 1995.

- Radford, D.W., “Electric/Solar Cars”, Presented at the 1991 Spring Conference, Rocky Mountain Electrical League, Colorado Springs, CO., May 1991.

- Radford, D.W., “Solar Powered Vehicles”, Presented at the 6th Annual Mobile Sources/Clean Air Conference, National Center for Vehicle Emissions Control and Safety, Boulder, CO., September 1990.

Related Theses

- Mercera, R., “Project Management for CSU Solar Rayce Car”, MS Thesis, Colorado State University, Fall 1991.

- VanGoethem, D.J., “Design of Structurally Coupled Composite Beams Under Combined Bending and Torsional Loading”, MS Thesis, Colorado State University, Fall 2001.