Primary Objectives

|

Active Research Projects

|

Completed Research Projects

|

Key Facilities & Capabilities |

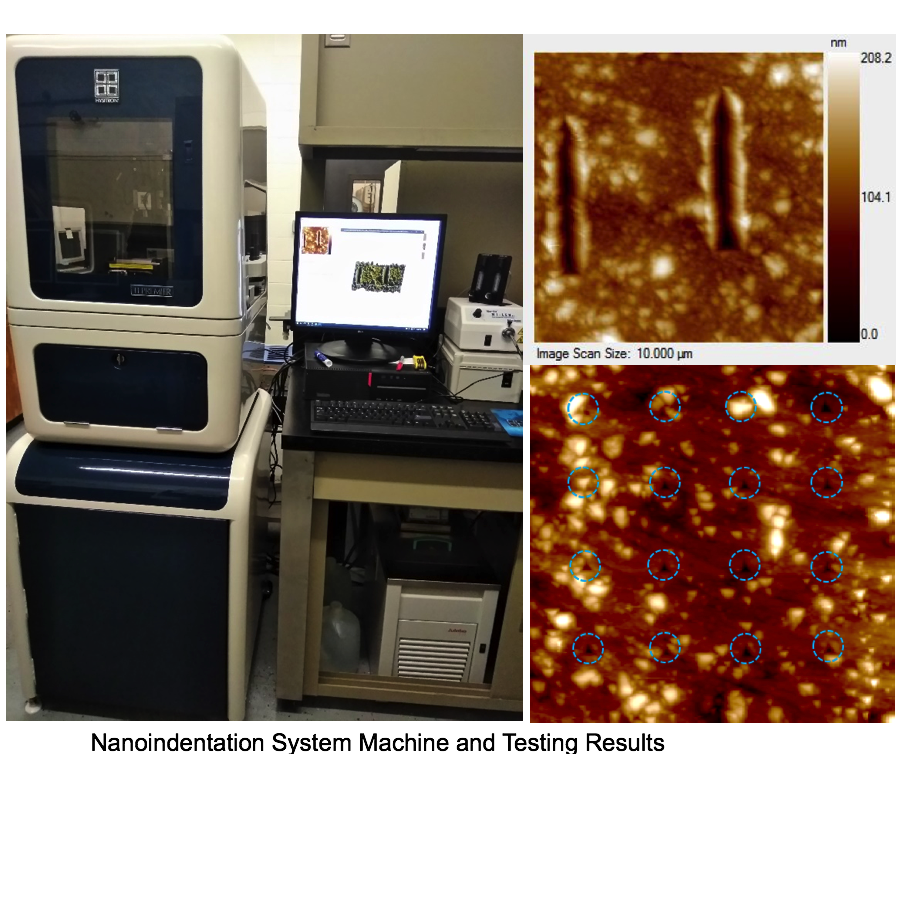

Nanoindentation System (Hysitron TI Premier_xSol with 400°C heating stage)

|

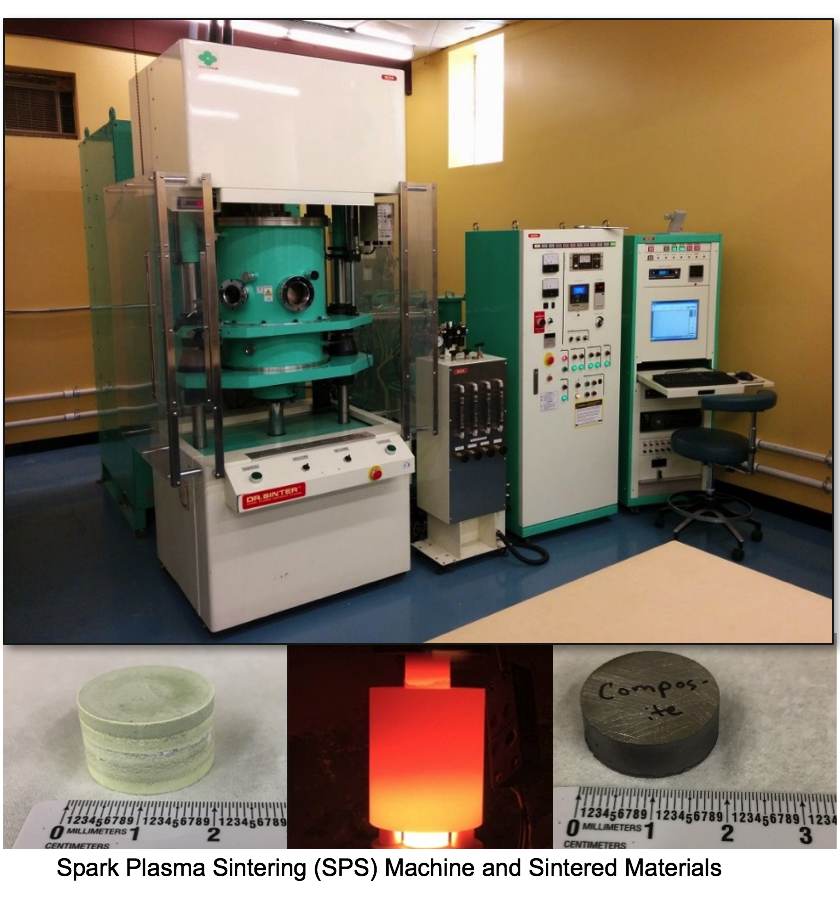

Spark Plasma Sintering Spark plasma sintering (SPS), which is also often referred as field assisted sintering technique (FAST) or pulsed electric current sintering (PECS), applies a pulsed direct current (DC) to an electrical-conductive die (commonly graphite) to densify the powder compact in the die. The pulsed DC also passes through the powder compact in case of conductive samples. Joule heating plays a dominant role in the densification of powder compacts. In contrast to other sintering techniques, such as hot pressing, where the heat is provided by external heating elements, the heat generation in SPS is internal. Near theoretical density can be achieved at lower sintering temperature and within a shorter time length (within a few minutes) compared to conventional sintering techniques due to the high heating or cooling rate (up to 800 K/min) facilitated by Joule heating. The fast sintering rate in SPS ensures it has the potential of densifying powders with nanosize or nanostructure while avoiding coarsening.

|

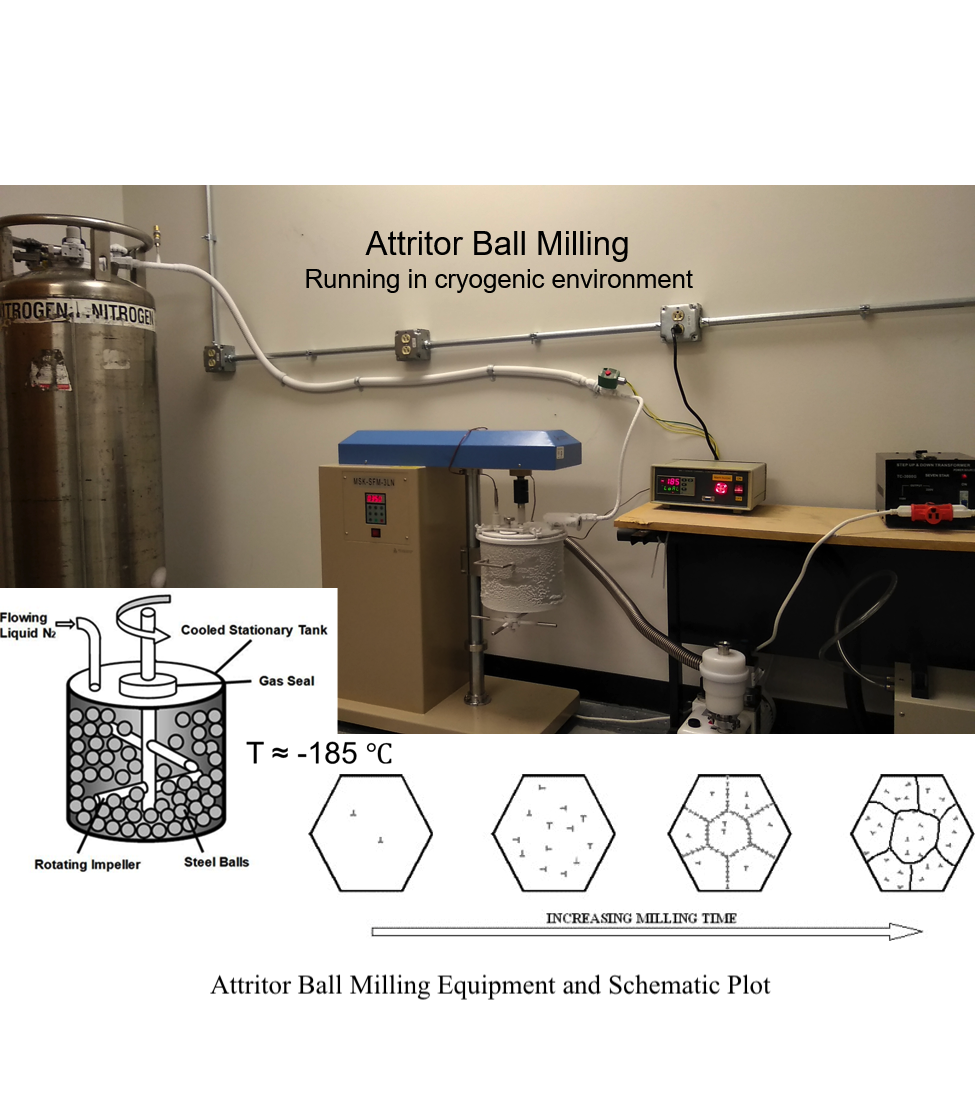

Attritor Ball Milling In the context of Ma’s research group, cryomilling is a mechanical attrition technique in which powders are milled in a slurry formed with milling balls and a cryogenic liquid. The uniqueness is that the powder is in intimate contact with the cryogenic liquid, compared to deformation occurring at cryogenic temperatures by chilling a milling vessel externally without intimate contact between the powder and the cryogenic liquid, for which the term cryomilling has also been used. Cryomilling is capable of fabricating nanocrystalline powders, strengthening the materials through grain size refinement and the dispersion of fine, nanometer-scale particles. As a powder metallurgy technique, it is usually followed by a consolidation step (sintering or other thermo-mechanical processing techniques) to produce bulk samples. The apparatus of cryomilling can be used for other functions such as mechanical alloying, mixing and grinding of powders.

|

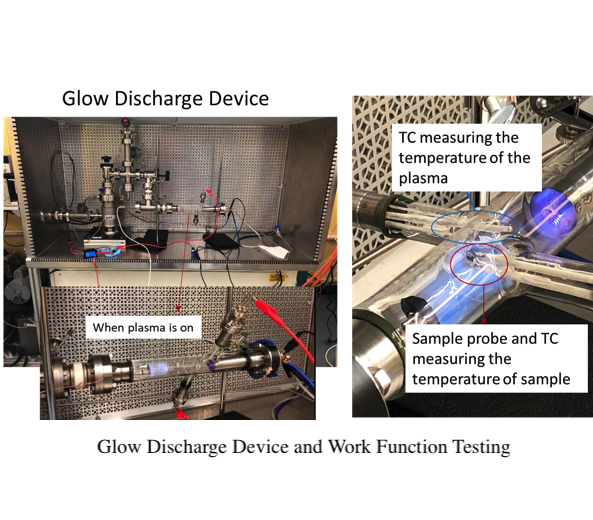

Glow Discharge Device A glow discharge is a plasma formed by the passage of electric current through a gas. It is created by applying a voltage between two electrodes in a glass tube containing a low-pressure gas (Argon, Nitrogen, etc.). In a glow discharge, the cold plasma can be used to test the electromagnetic properties of materials. Due to its low electromagnetic radiation, it provides a safe and environmental-friendly processing on material surface modification.

|

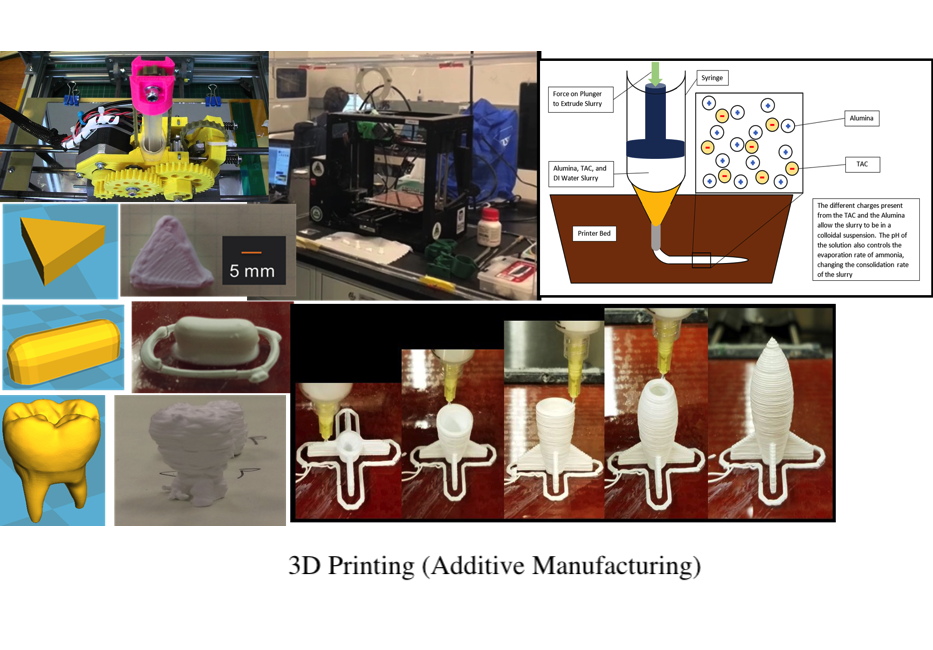

3D Printer (Additive Manufacturing) Ma's group explore an additive manufacturing approach, named direct coagulation printing (DCP), to make ceramic components with both basic and complex geometries without using binder materials. it relies on the coagulation effect rather than heat-assisted sintering. It is binderless and only involves ambient temperature. |