Thin film deposition is the backbone for many industries including thin film PV, semiconductor, flat panel display, LED laser manufacturing and others. The US is the world leader in manufacturing thin film PV. The research at the Center has highlighted the strong need for computational modeling of deposition processes for the thin film PV fields.

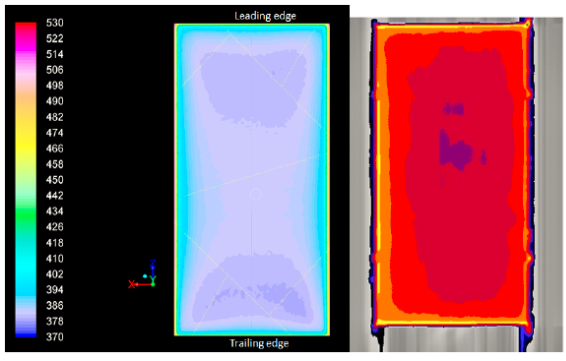

Our aim is to bring accurate Simulation Based Engineering Science (SBES) to the thin film industry and lead to significant economic benefits. The foundation of the Center’s capabilities is the thermal modeling of many industrial scale systems that have been completed by our group. Thermal simulation methods were utilized to design processing hardware and model industrial systems for the production of thin film PV modules (100 MW/yr.). The exact geometries of the industrial hardware are modeled and the resultant temperature distribution predicted by thecomputations is within +/- 2% of the experimental measurements.

The Center’s simulation research includes mechanical, thermal and computational fluid dynamics (CFD) models will include thermal aspects as well as generation, transport and deposition of vapor species. Our current research thrust involves extending the computational simulation methods to vapor species and ultimately enable a predictive understanding of film properties including the film thickness, film uniformity and microstructure. This work is supported by the National Science Foundation’s Accelerating Innovation Research Technology Translation program.

The CdTe solar cell manufacturing process developed at Colorado State University used a vapor source that utilized infrared heating lamps as the heating source. This was used in the initial research system that was used to develop the inline CdTe solar cell manufacturing method used in industry. This system has since been redesigned to improve its ability to function as a more versatile research tool.

The CdTe solar cell manufacturing process developed at Colorado State University used a vapor source that utilized infrared heating lamps as the heating source. This was used in the initial research system that was used to develop the inline CdTe solar cell manufacturing method used in industry. This system has since been redesigned to improve its ability to function as a more versatile research tool.

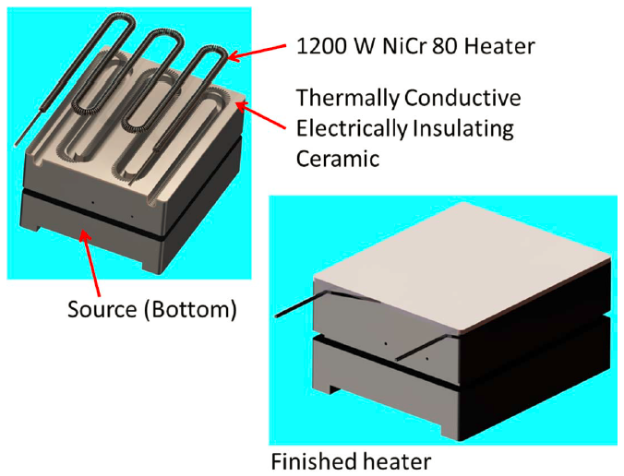

Embedded NiCr Heating for ARDS Deposition Source

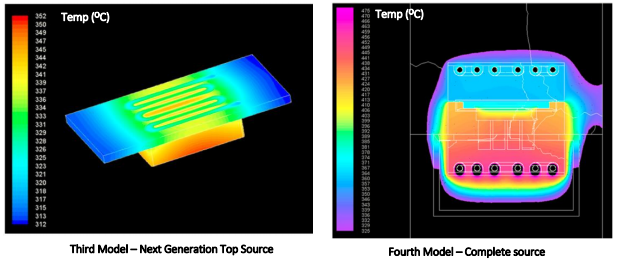

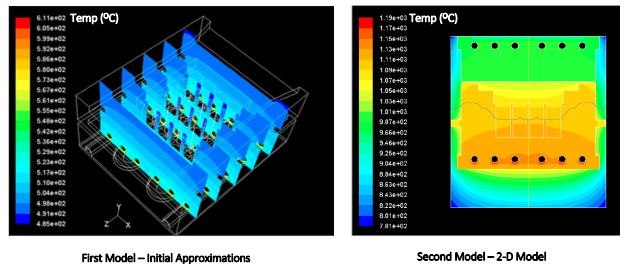

This study focused on the modeling efforts used in the development and understanding of an embedded NiCr heating unit for the vapor source. The traditional infrared heating lamps, while effective, were inefficient. A new design consisting of a NiCr heating element imbedded in to the graphite deposition crucible, was developed as a more efficient and robust replacement to the infrared lamps. Four distinct models of increasing complexity were developed using the heat transfer modeling capabilities of ANSYS Fluent. The first two models helped to determine the overall thermal uniformity and the ability of the new heating designs ability to reach the needed temperatures of the deposition processes.

The third model discussed in this study, aided in the development of the top heater that

The third model discussed in this study, aided in the development of the top heater that

would maintain the desired steady state temperature at the process station used to deposit CdS films. The final model developed contained a higher level of detail used to determine the validity of previous assumptions and to gain an understanding of the internal temperature profile of the completed source.

This modeling effort was extended to the system used in industry. The experimental data was compared to the modeled data verifying the model accuracy. The calculated temperatures were within 2.5% of the measured temperatures. The modeling efforts of CSU’s deposition systems has proved the usefulness of CFD modeling as an important tool to equipment development and characterization.