A spinoff of the ion thruster is the broad-beam ion implanter. It utilizes the same basic hardware as the thruster but the ion beam, instead of being used to produce thrust, is directed onto the surfaces of various mechanical engineering components in vacuum chambers. The resulting treatment of these surfaces can increase their resistance to wear and corrosion, as well as reduce the friction between surfaces in components such as bearings.

Laboratory facilities include both gaseous and metallic ion implanters which produce ion beams with energies that range from 1 to 100 keV and beam current densities that are as high as 5 mA/cm2. Tribological test facilities include a rolling contact fatigue tester, a block-on-ring wear and friction tester and pin-on-disc wear and friction testers that can be operated over a wide range of temperatures and in controlled environments. These environments may involve for example, an atomic oxygen atmosphere that is representative of space and lubricated, ambient-air environments.

Research is aimed at defining and optimizing broad-beam ion implanters for rapid and, therefore, low cost processing of a wide range of materials (metals, ceramics and polymers). The present focus is on the production of boron-, nitrogen- and carbon-implanted layers on steel surfaces that are both thick and wear resistant.

For more information on the ion implantation and ion beam processing that has occurred in this lab see the following papers

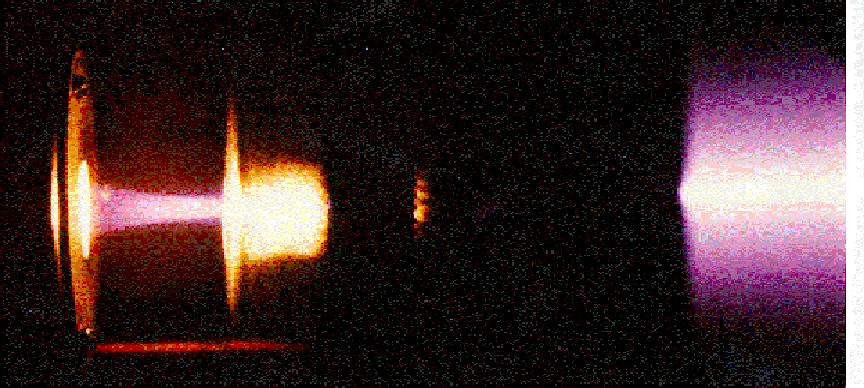

The picture on the left is the accelerator grids to the high voltage gas implanter. The picture on the right is of a plasma beam impinging on a graphite plate.