Nanostructured Polymer Systems

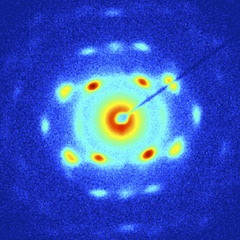

We focus on the design of polymeric systems, typically functionalized block copolymers, that have a latent capacity to self-initiate structuring or re-structuring processes during processing and/or use, and for which the nanostructure generated provides a performance advantage in the intended application. For example, we have found that our ability to control network nanostructure through self-assembly can be used to overcome the intrinsic fragility of highly swollen polymer networks, and provide exceptional mechanical elasticity and fatigue resistance.

Hydrogels and Ionic Elastomers

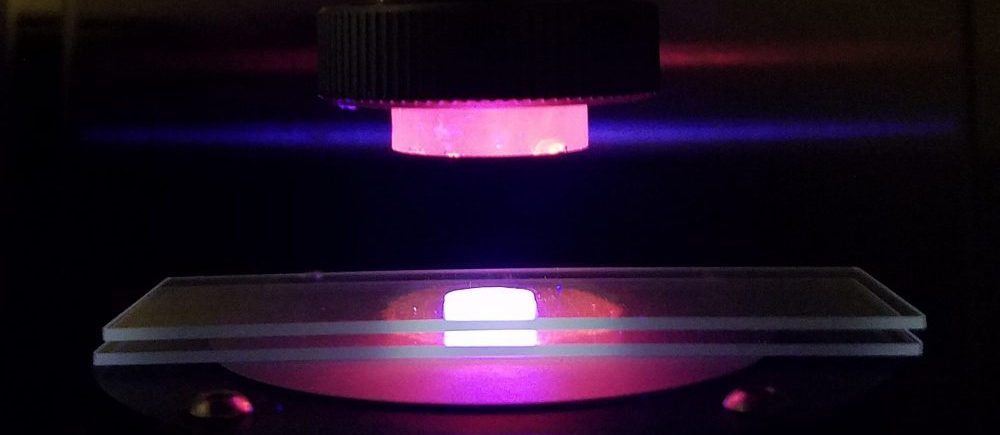

We have begun developing strategies for tuning the mechanical properties of such swollen networks using light, incorporating direct photopatterning capabilities, improving the toughness of such systems once swollen, and building in improved resistance to fracture – all characteristics aimed at advancing the utility of these unique materials.

Membrane Development

Block copolymers that possess one block which is highly charged have implications in a number of membrane applications where transfer of charged species is critical. This project established the hydrogel network architecture, when swollen in ionic liquids in lieu of aqueous media, produced high performance CO2 separation membranes pushing the current limits of combined selectivity and permeance. This project was also performed in collaboration with the Gin and Noble groups at CU Boulder

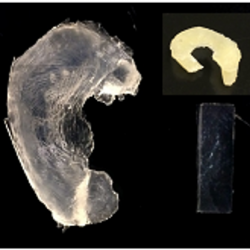

Biological Soft Tissue Mimics

A major area of research emphasis has been to use our knowledge of tuning swollen network properties to develop biomechanically viable artificial soft tissues, as replacement materials for the meniscal tissue of the knee, or the fibrocartilage of the intervertebral disc. We have worked collaboratively with the Haut Donahue group (School of Biomedical Engineering at CSU and UMass, Amherst) to both establish the mechanical properties of ovine and human meniscal tissues,while developing a hydrogel based construct that can match their mechanical performance. Most importantly, we have been able to optimize the synthetic meniscus nanostructure to exhibit exceptional fatigue resistance, Our group is now working to develop 3D printable versions of these constructs, such that personalized implants could be printed directly from MRI or CT source files for any patient.