Demonstration of Bio-Alcohol/FAME Blends with Tailored Low Temperature Chemistry for Enhanced Homogenous Charge Compression Ignition (HCCI) Engine Performance

A C2B2 Research Project

Principal Investigator:

Anthony J. Marchese, Ph.D.

Associate Professor

Department of Mechanical Engineering

Colorado State University

Fort Collins, CO 80524

Email: marchese@colostate.edu

Telephone: (970) 491-2328

Rationale

Homogeneous charge compression ignition (HCCI) engines have the potential to produce the high fuel economy of a compression ignition (CI) engine, with the low emissions of a spark ignition (SI) engine. However, despite significant research in the past decade, at least four major technical hurdles still exist which prevent HCCI from becoming a practical alternative to SI or CI engines: (1) poor low-load combustion efficiency, (2) very limited operating map at higher loads, (3) limited understanding of fuel-composition effects on operating limits, and (4) poor control of combustion-phasing over a broad range of loads/speeds. At higher loads, the high energy release rate and the correspondingly rapid pressure-rise rate leads to strong acoustic oscillations, resulting in excessive engine noise and possibly engine damage. Recent research suggests that the ideal HCCI fuel would have characteristics that are intermediate between gasoline and diesel fuel. Specifically, the ideal HCCI fuel would exhibit moderate low-temperature reactivity (i.e. less reactive than diesel fuel but more than gasoline) and sufficient volatility for well-controlled mixture formation. It is hypothesized here that an ideal HCCI fuel can be realized by considering mixtures of alcohols and fatty acid methyl esters (FAME), both of which have already seen considerable growth in production via currently available biological sources (corn, soybean, animal fat, etc.) and whose potential for future growth is vast if production from new sources (cellulosic sources, algae, etc.) continues to progress toward fruition.

Objectives

The proposed project will examine the HCCI characteristics of bio-derived alcohols (bio-ethanol, bio-butanol), bio-derived fatty acid methyl esters (FAME), and their blends. Specifically, alcohol/FAME blends will be formulated with various octane number/cetane number/volatility characteristics and experiments will be performed in a rapid compression machine (RCM) which enables the single shot compression ignition of a homogeneous fuel/air mixture. To quantify the combustion chemistry of these fuel mixtures during the induction period and transition to hot ignition, four complementary systems will be integrated with the RCM: a passive optical system that measures CH2O* and OH* chemiluminescence, a gas sampling system for quenching and analyzing the post compression gases using a Fourier Transform Infrared (FTIR) spectrometer, a Cambustion CLD 500 fast NOx analyzer and a laser diagnostic system that enables quantitative measurements of formaldehyde (as a marker for low temperature reactivity) and OH (as an indicator of high temperature chemistry) via planar laser induced fluorescence (PLIF). The RCM experiments will be simulated using a multi-zone modeling technique, which includes detailed chemical kinetics but also allows for consideration of charge/thermal stratification. Detailed alcohol/FAME blend chemical kinetic mechanisms will be developed from existing methyl decanoate, ethanol and n-butanol mechanisms.

Progress to Date

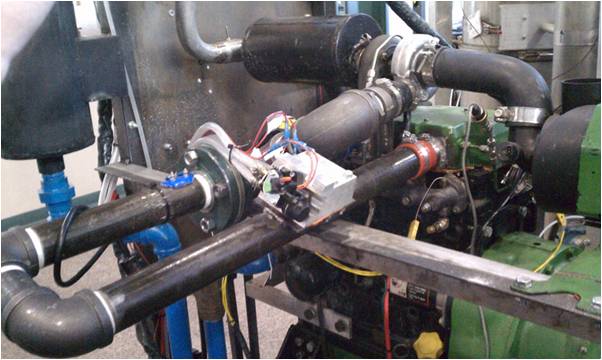

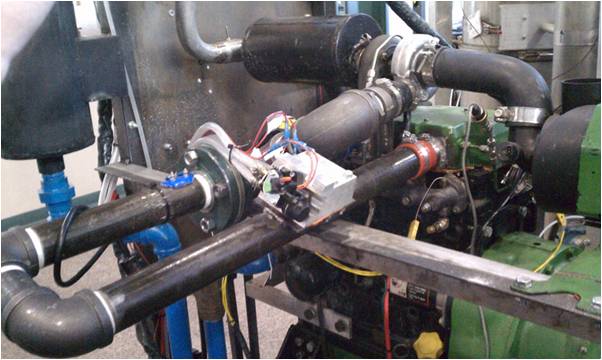

In addition to the RCM experiments, an existing John Deere 4024T diesel engine is currently being converted to operate in HCCI mode with these alcohol/FAME blends. For comparison with numerical combustion models, detailed alcohol/FAME blend chemical kinetic mechanisms are being developed from existing methyl decanoate, methyl oleate, ethanol and n-butanol mechanisms.Thus far, we have found that existing detailed chemical kinetic mechanisms for methyl esters (methyl decanoate, methyl oleate, etc.), which contain sub-mechanisms for ethanol do not accurately reproduce ignition delay predictions of existing detailed ethanol mechanisms. Accordingly, a major effort in this research is currently aimed at updating these mechanisms. From an experimental standpoint, we recently completed the conversion of our diesel engine into an HCCI engine and we demonstrated HCCI combustion for primary reference fuels. The figures below are photographs of the John Deere 4024T engine (left)and completed HCCI intake manifold (right) including fuel injector or heater.

Project Personnel

Anthony Marchese, PI

Marc Baumgardner , Ph.D. Candidate

Last Updated: April 15, 2011