Development of a 1-1 Second Drop Tower Apparatus for Fundamental

Combustion

and Fluid Dynamics Research

An NSF Major Research Instrumentation (MRI)

Award

Principal Investigator:

Anthony J. Marchese, Ph.D.

Associate Professor

Department of Mechanical Engineering

Colorado State University

Fort Collins, CO 80524

Email: marchese@colostate.edu

Telephone: (970) 491-2328

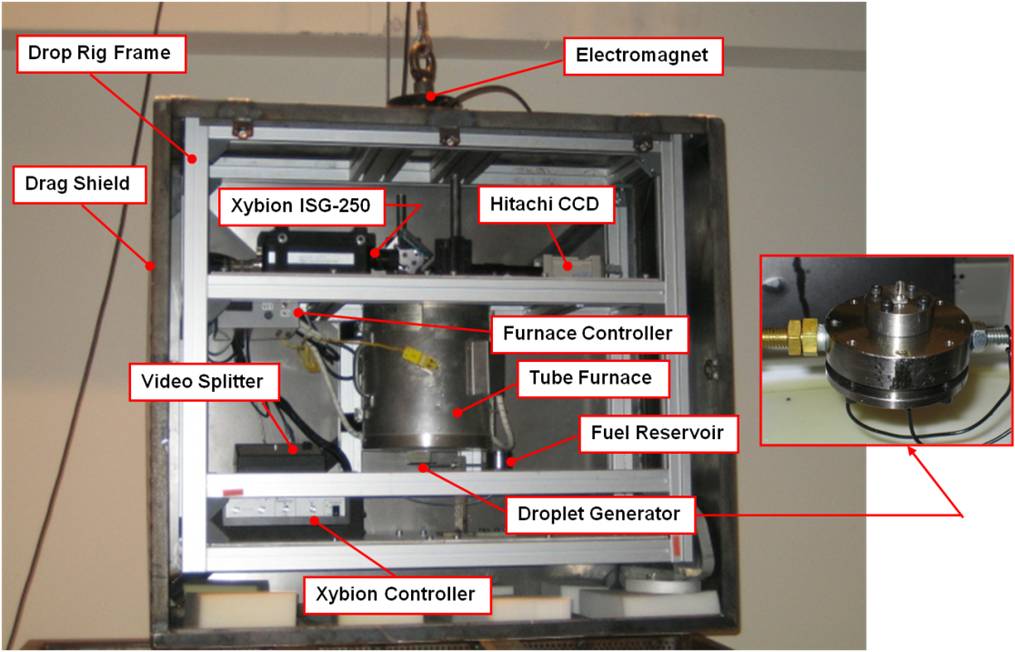

Project Summary

In 2004, our research group was awarded an NSF Major Research Instrumentation Award to develop a new 1.1-second drop tower apparatus and associated instrumentation that enabled researchers to perform fundamental studies in combustion and fluid dynamics. The drop tower was designed by incorporating systems from several existing drop towers, including the 2.2-second drop tower located at NASA Glenn Research Center, a drop tower at Cornell University, and a drop tower located at the University of Texas at Austin. Three main systems were developed for the new drop tower: a hoist/release mechanism, a deceleration device and a experimental drop rig. The latter system was developed to be compatible with the NASA 2.2-second drop tower specifications. In fact, the new drop tower was designed to accommodate any NASA 2.2-second drop rig. The purpose of the hoist/release mechanism is to hoist the drop rig and to release it into free-fall with minimal jitter. Any jitter during release results in degradation of the microgravity level during free fall. Components of the release mechanism include two W4x13 I-beam supports, two pulleys, an electric winch (SuperWinch 1723), and an electromagnet (Magnetech Corp. R-6030-24). The winch is attached to the electromagnet via the two pulleys, and the electromagnet attaches to the drop rig by use of a steel button. After the rig is hoisted to its highest position and reoriented to fall smoothly, the power to the electromagnet is cut, thereby releasing the rig into free fall. The bottom of the tower contains the deceleration device, which is used to slow down and ultimately stop the rig. The device consists of an airbag with four 6-inch blast gates which open upon impact of the experimental drop rig to allow the release of air. One of the openings also serves to inflate the airbag via a radial blower attached to the outside. Underneath the airbag sits a 12” polyurethane foam mat which serves to soften the final stage of deceleration. The airbag and mat are confined in a welded steel cage that was designed and built in-house. In all, the drop rig experiences approximately 1.1 seconds of free fall from the time it’s released until it hits the top of the airbag.

Project Personnel

Anthony Marchese, PI

John Chen, co-PI

Matt Hammill, '03,'05

Tim Vaughn, '05,'06

Fred Bellottie, '05

Scott Jurewicz, '05

Greg Soriano, '06

Colleen Boland, '05

Justin Pusey, '06

Last Updated: August 5, 2004