Characterization of Particulate and Gaseous Emissions from Algal Methyl Esters

A Sustainable Biofuels Development Center Research Study

Principal Investigator:

Associate Professor

Department of Mechanical Engineering

Colorado State University

Fort Collins, CO 80523-1374

Rationale

Studies have shown that the magnitude of pollutant emissions (e.g. NOx and PM) from diesel engines operating on fatty acid methyl esters (i.e. FAME biodiesel) are directly linked to the chemical structure of the triglycerides present in the bio feedstock. Specifically, NOx emissions have been shown to increase with increasing number of double bonds in the hydrocarbon chain and decrease with increasing carbon chain length; and PM emissions have been shown to decrease with increasing carbon chain length. However, no study has been done to date to characterize the pollutant emissions of algae-derived FAME, which have far different fatty acid composition than FAME derived from typical vegetable or animal fat feedstocks. Accordingly, the goal of the present study is to examine the effect of the chemical structure of algal bio-crude feedstocks on diesel pollutant formation in a John Deere 4024T diesel engine operating on algae-derived FAME biodiesel.

Objectives of this Study

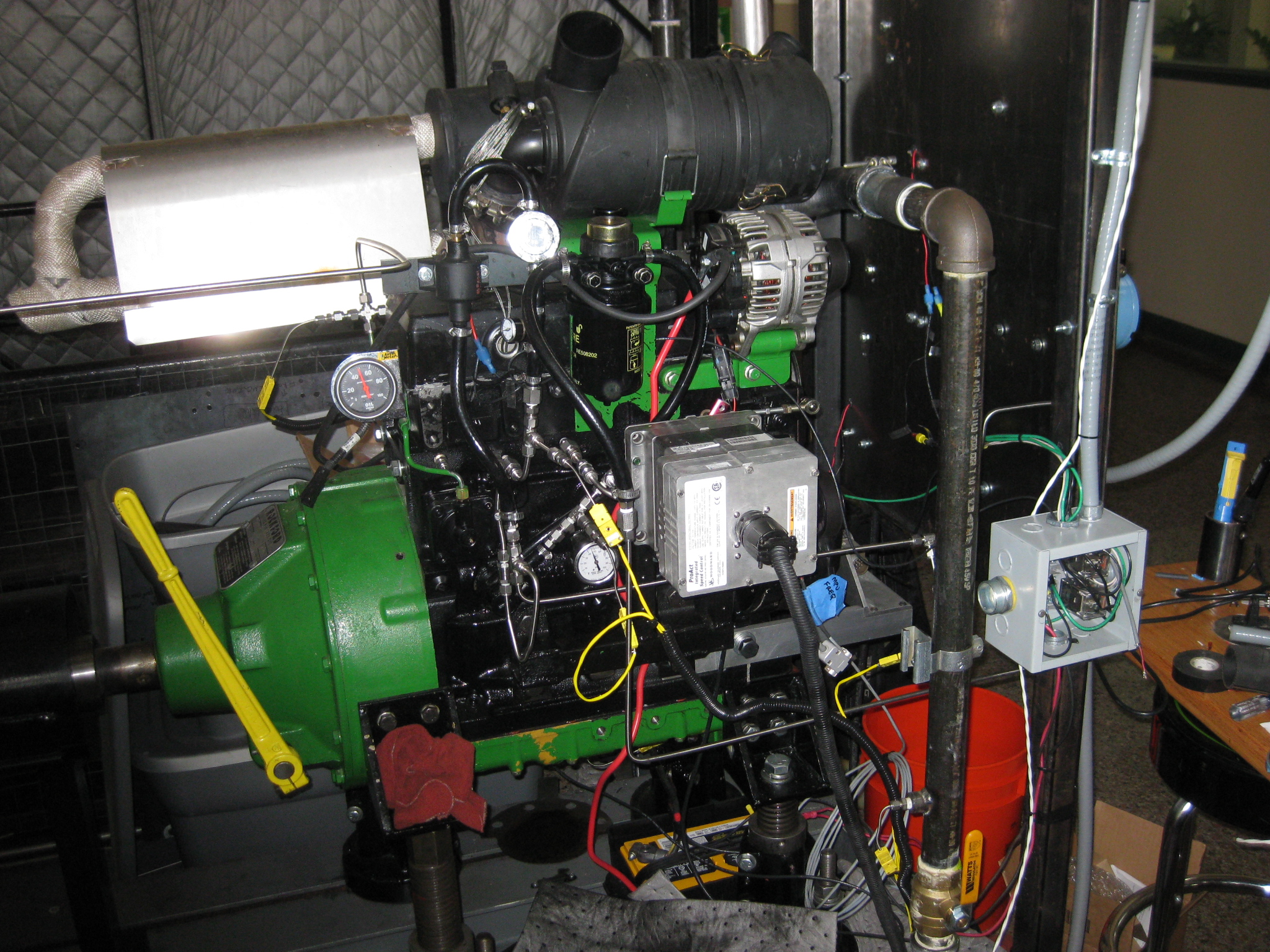

Engine emissions tests were conducted with the two algal methyl ester formulations, soy methyl ester, rapeseed (canola) methyl ester and ultra low sulfur petroleum diesel (ULSD), along with 20% blends of each of the methyl esters with ULSD (i.e. B20). Emissions testing was performed using a John Deere 4024T, non-road diesel engine meeting USEPA Tier 2 emissions regulations. This 4-cylinder engine has 2.4 L displacement, turbocharged aspiration and is rated at 56 BHP. Tests were performed using the steady-state C1 Test Cycle as specified in ISO 8178-4 guidelines.

The following systems were employed to measure gaseous and particulate exhaust emissions:

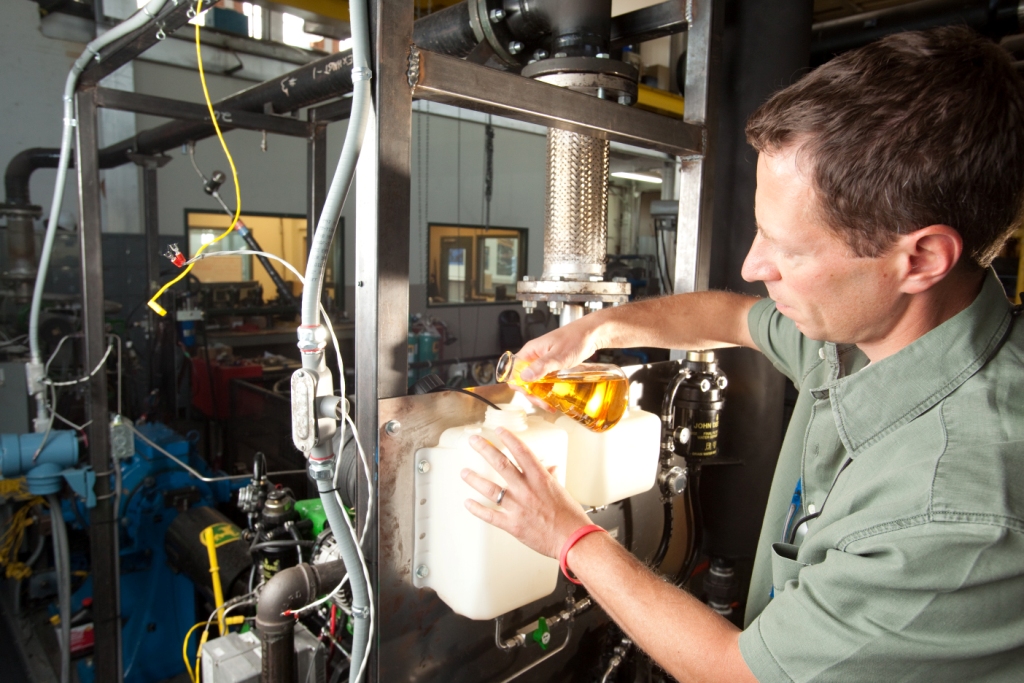

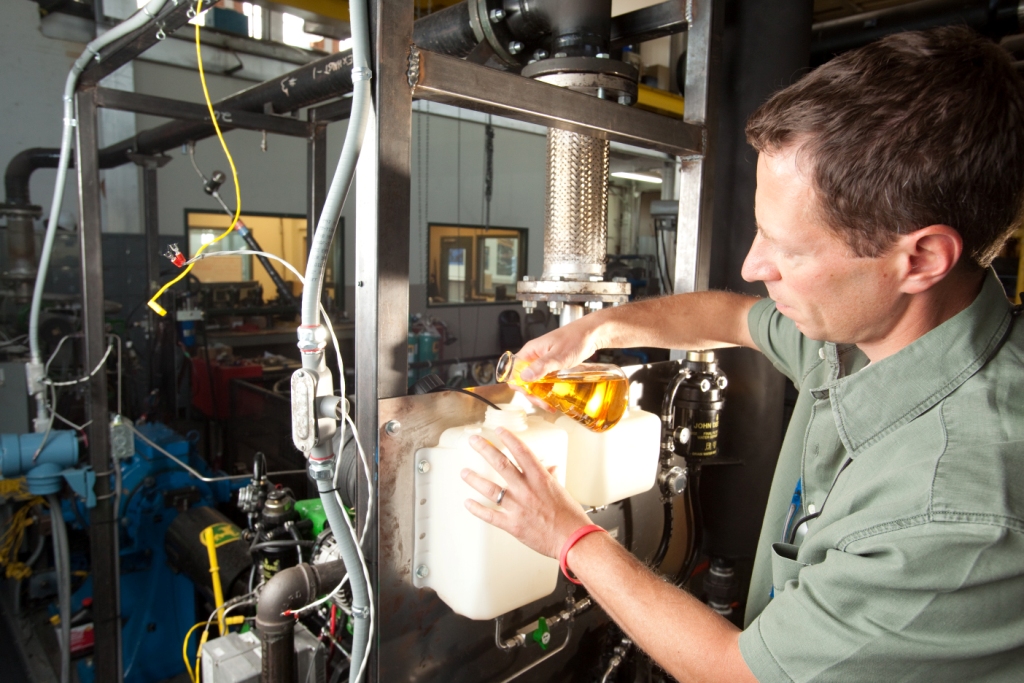

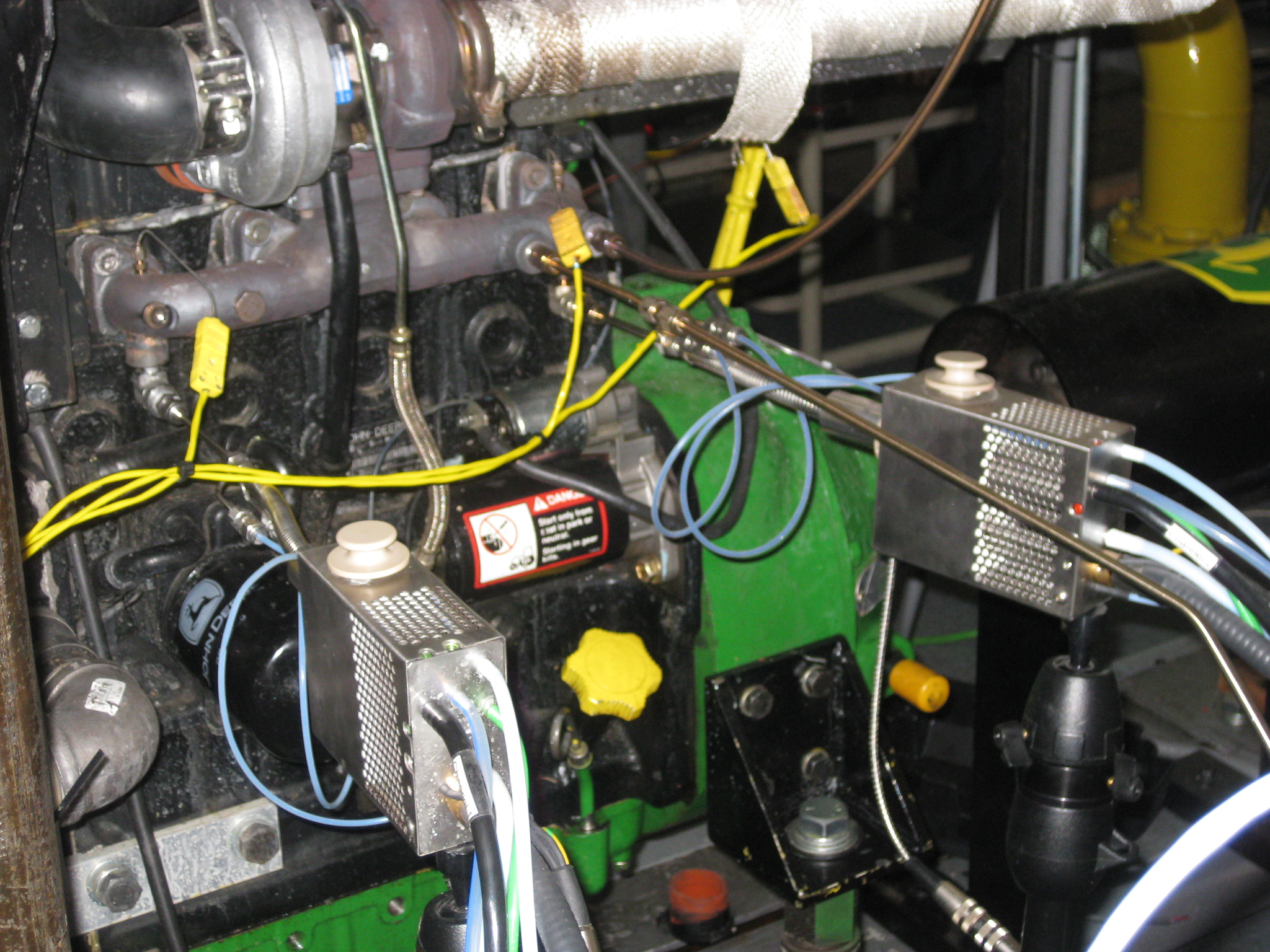

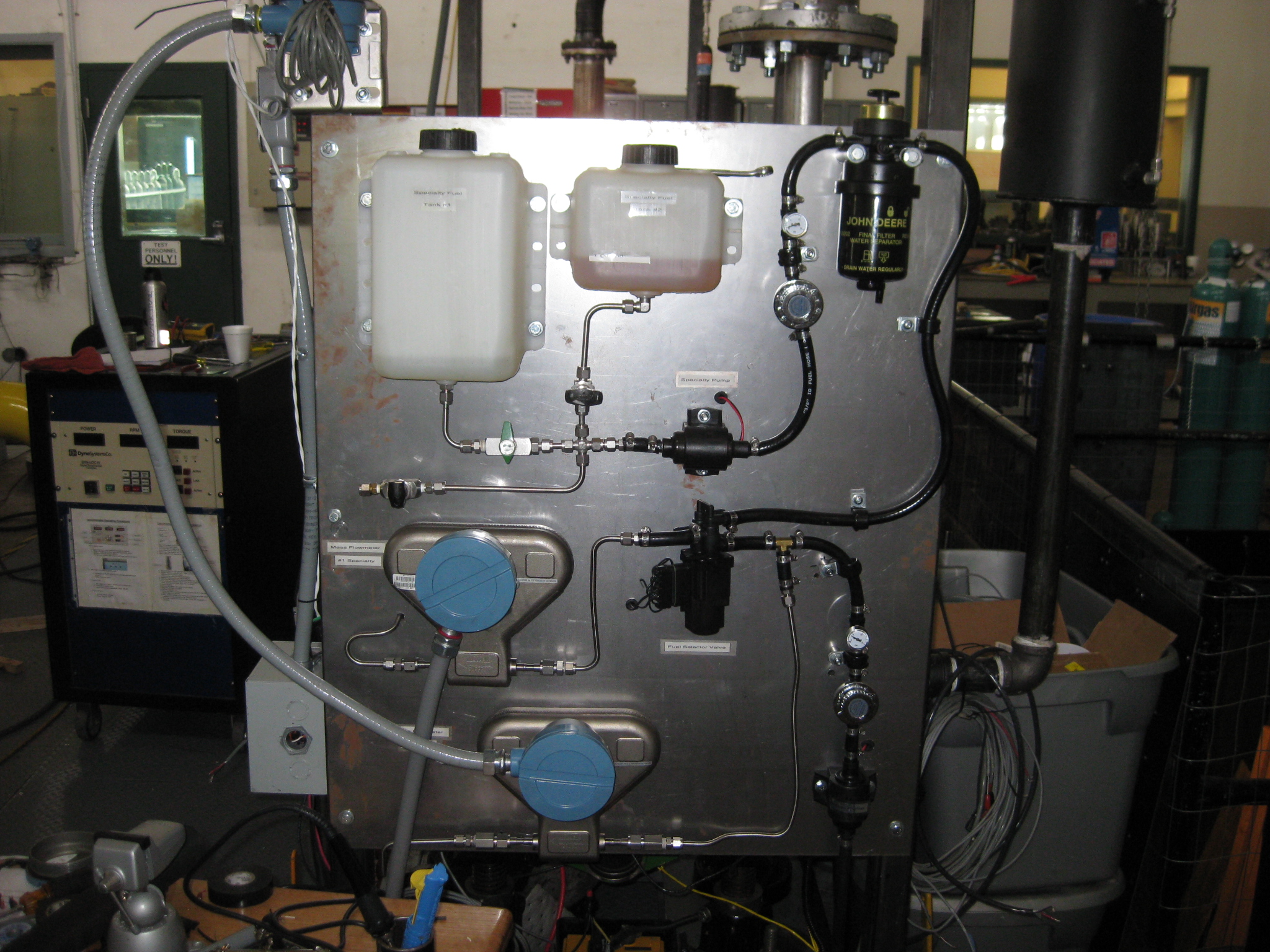

To accommodate testing of low quantities of algae-based specialty fuels, the 4024T engine was modified to enable direct injection of the specialty fuel into 1 cylinder upon command, with the remaining three cylinders operating on petroleum ULSD. The system included two Micro Motion CFM010 Coriolis mass flow meters to measure the specialty and ULSD mass fuel flow rates. Exhaust gases were sampled directly from the specialty fuel cylinder and compared against those sampled from one of the ULSD cylinders. The figures below shows the 4024T engine in test configuration, the two sample heads for the Cambustion CLD500 Rapid NOx analyzer (located in the ULSD and specialty fuel cylinder exhaust ports), and the specialy fuel feed system.

Last Updated: October 7, 2009