|

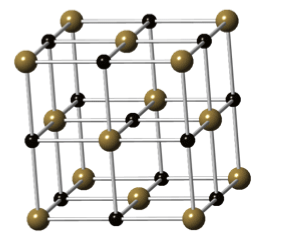

Mechanics of Transition Metal Carbides and Nitrides Transition metal carbides and nitrides comprise a class of materials with the highest melting known to man. TaC, HfC and their alloys can have melting temperatures around 4000 C. Their ultra refractory nature make them candidate materials for a wide range of high temperature applications. However, their high melting temperatures makes them difficult to routinely test. Our research attempts to answer fundamental questions regarding how these materials deform, how different sub-stoichiometric phases and their microstructure impact the materials property as well as understanding the fundamentals of why they form. Our research also aims at understanding the role of point defects and alloying elements in these unique materials. |

|

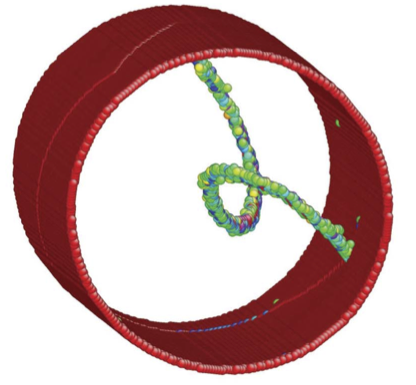

Nanomechanics The high surface area to volume ratio of nanomaterials and nanostructures gives these materials properties that are unique from their bulk counterparts. This includes mechanical properties, where flow strengths can be an order of magnitude greater. Our work is interested in provided simulations to compliment experiments in understanding, predicting and developing models of the behavior of these novel materials. |

|

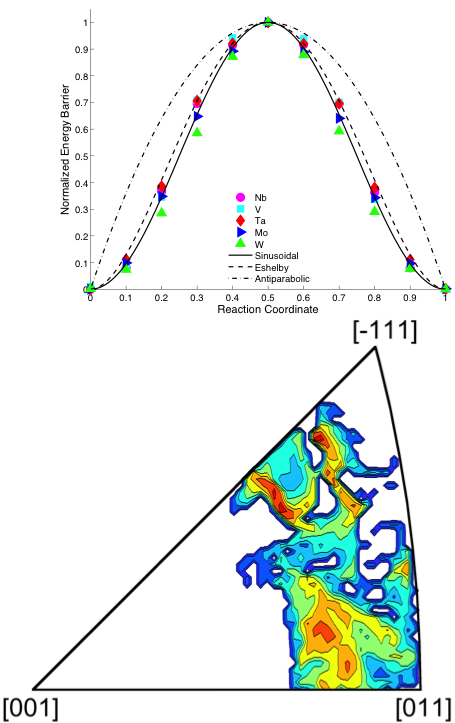

Multiscale Modeling of BCC Transition Metals The BCC transition metals (Fe, Cr, Mo, W, V, Nb, Ta) have a wide range of applications, many of which are structural. Iron is the basis of steel, which is can be argued to be the keystone of a modern society. Niobium, tantalum, molybdenum and tungsten are all refractory (melting temperatures above 2000 C) metals and are exploited for high temperature applications where ductility and formability are important. We are developing models of their mechanical properties that span both length and time scales, from atoms to the continuum. This includes combining simulations using electronic structure density functional theory, classical atomistics, dislocation dynamics, crystal plasticity and classical continuum plasticity models. |