Development of a Tier 4 Biomass Gasifier Cookstove

A Department of Energy Project

Co-Principal Investigator:

Anthony J. Marchese, Ph.D.

Associate Professor

Department of Mechanical Engineering

Colorado State University

Fort Collins, CO 80524

Email: marchese@colostate.edu

Telephone: (970) 491-2328

Rationale

More than half of the world's population uses solid fuel, such as wood, charcoal, dung, agricultural waste, or coal, as the primary fuel source in their households. The majority of this portion of the population lives in Africa, Southeast Asia, and the Western Pacific. Because much of this solid fuel is used to cook food, much effort has gone towards designing improved household cookstoves that use solid fuel more efficiently and/or produce lower emissions of carbon monoxide and particulate matter. The goal in reducing emissions from household cookstoves is to reduce the incidence of the many adverse health effects that are associated with indoor air pollution: acute carbon monoxide poisoning, acute lower respiratory infections, chronic obstructive pulmonary disease, lung cancer, tuberculosis, asthma, cataracts, low birth weight and various other cardiovascular problems.

With the goal of alleviating these health impacts in mind, an International Workshop Agreement (IWA) containing a set of proposed ISO standards for improved cookstoves was established in February 2012 (ISO International Workshop on Clean and Efficient Cookstoves, 2012). The standards include a tiered rating system in which a stove receives a rating of 0 to 4 in categories such as high power efficiency, low power efficiency, high power carbon monoxide (CO) emissions, low power CO emissions, high power particulate matter (PM) emissions, and low power PM emissions. One of the goals associated with the establishment of this rating system was to encourage the development of improved cookstoves that meet Tier 4 standards. It is hoped that such cookstoves will have sufficiently low emissions to produce a measureable improvement in the health of users.

Objectives

This DOE funded project focuses on understanding how various parameters affect the combustion process occurring within a TLUD semi-gasifier cookstove and using this understanding to design a semi-gasifier cookstove that exhibits very low emissions under a variety of operating conditions. The project involves four main areas: experimentation with a semi-gasifier test bed, development of a fuel bed model with incorporated chemical kinetics, high-speed planar laser induced fluorescence (PLIF) imaging of the secondary combustion zone in an optical semi-gasifier cookstove, and development of a computational fluid dynamics (CFD) model of the secondary combustion zone. The experimental data obtained using the test bed, including information about the rate at which the primary combustion zone propagates through the fuel bed and the composition of the gases produced, will be used to validate the fuel bed model. Experimental data from the high-speed PLIF experiments will be used to validate the CFD model.

Progress to Date

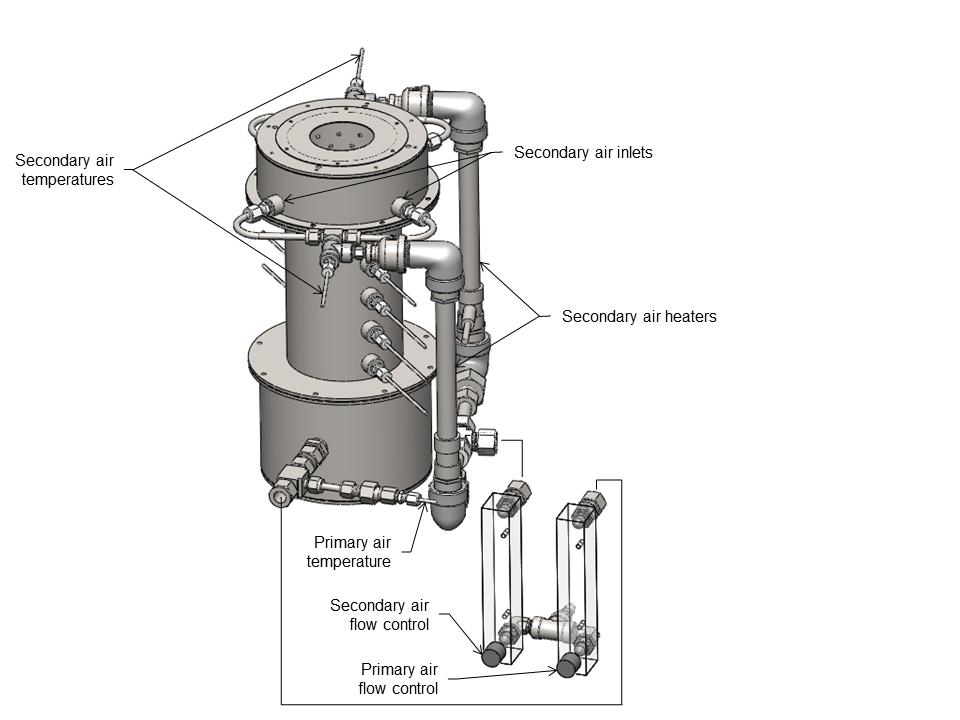

A semi-gasifier test bed was constructed that enables the variation and control of numerous operating parameters such as primary air flow rate, secondary air flow rate, secondary air temperature, primary air inlet geometry, secondary air inlet geometry, pot gap, and fuel type. In the first set of experiments, the power output of the stove, velocity of the reaction front, carbon monoxide emissions, and particulate matter emissions were recorded as the primary and secondary air flow rates were varied. The hypothesis is that varying the ratio of secondary to primary air would affect the emissions from the stove and varying the overall primary air flow rate would affect the power output of the stove.

Project Personnel

Morgan DeFoort, PI

Anthony Marchese, co-PI

Azer Yalin, co-PI

Xinfeng Gao, co-PIJessica Tryner, Ph.D. Candidate

Alton Luder, Post Doc

Last Updated: March 18, 2014