Advanced Biofuels Combustion and Characterization Laboratory

Director:

Associate Professor

Department of Mechanical Engineering

Colorado State University

Fort Collins, CO 80523-1374

Advanced Biofuels

The 2007 Energy Independence and Security Act mandates the production of at least 21 billion gallons of advanced biofuels by 2022. A major focus of the Advanced Biofuels Combustion and Characterization Laboratory at the CSU Engines and Energy Conversion Laboratory is to ensure that these next generation biofuels are "fit-for-purpose" as drop in replacements for compression ignition engines, spark ignited engines and gas turbines.

Equipment and Resources

The Advanced Biofuel Combustion and Characterization (ABC2) Laboratory contains resources for characterization of combustion chemistry, pollutant formation, engine emissions and fuel/lipid/feedstock properties of advanced biofuels. The ABC2 laboratory is located at the Engines and Energy Conversion Laboratory, which is a unique research facility at Colorado State University with emphasis on engines, fuels, and energy conversion technology. The 24,000 ft2 EECL has extensive facilities for testing of engines ranging from 1 hp to 2,500 hp and is the only university laboratory in North America with capabilities for experimental research on large bore engines. Selected capabilities at the ABC2 Laboratory are summarized below.

1. Fuel Characterization

In terms of fuel analysis, the major emphasis of the ABC2 Laboratory is on characterization of bio-derived fuel properties to ensure that advanced biofuels are fit-for-purpose as substitutes for petroleum based fuels. Accordingly, the ABC2 Laboratory is equipped with a list of analytical instrumentation for fuel analysis that currently includes the following:

• Metrohm 831KF Coulometer (ASTM D664 Acid Number)

• Metrohm 888 Titrando (EN1411 Iodine Number)

• Anton Paar DSM5000 Speed of Sound Meter (Density, Speed of Sound, Bulk Modulus)

• SRI 8610D Gas Chromatograph (Fatty Acid Profiles of Methyl Esters)

• Petrolab 12-1771 Automatic Flashpoint Tester (ASTM D93)

• Metrohm 873 Rancimat Tester (EN 14112)

• Petrolab Copper Strip Corrosion (ASTM D130)

• Petrolab OL-14-2 Automated Cold Properties Tester (D2500, D6371)

• Anton Paar SVM3000 Viscosity Tester /Density (EN ISO 3675, D445)

• SpectroGenesis ICP Spectrometer for Ca, Mg, Na, K, P (EN 14538, D4951)

• Waukesha FIT Ignition Quality Tester for Derived Cetane Number (D7170)

• Petrolab C2000 Heating Value Calorimeter (D230)

• Centrifuge for Water and Sediment (ASTM D2709)

2. Combustion Research Systems

The ABC2 Laboratory contains numerous experimental systems for quantifying the combustion chemistry, pollutant formation and bulk combustion characteristics of hydrocarbons and advanced biofuels. These systems include low to atmospheric pressure premixed and opposed jet laminar flame burners that enable species measurement and transient compression ignition systems that facilitate combustion studies at conditions relevant to internal combustion engines. Diagnostics systems include direct gas sampling and optical diagnostics including laser induced fluorescence, laser induced incandescence and cavity ringdown spectroscopy. These experimental combustion systems are summarized below:

• Rapid Compression Machine – Manufactured by Marine Technology of Ireland, the rapid compression machine (RCM) simulates a single stroke of a compression ignition engine, enabling the measurement of ignition delay and speciation of homogeneous premixed fuel/air systems. The RCM includes a variety of systems necessary to operate and control the rapid compression process and to measure experimental parameters including instantaneous displacement and position of the piston during compression. The system also enables the measurement of dynamic pressure parameters during firing compression.

• Homogeneous Charge Compression Ignition Engine – A 4 cylinder turbocharged, 2.4 liter John Deere 4024T diesel engine, which is rated at 60 HP at 2800 RPM, has been modified to operate as a homogeneous charge compression ignition (HCCI) engine.

• Waukesha Fuel Igntion Tester (FIT) – In addition to the ability to perform Derived Cetane Number testing according to ASTM D7170, the FIT apparatus is a useful tool for fundamental combustion research aimed at quantifying low temperature chemistry effects of advanved fuels and/or advanced internal combustion engines.

• CLD 500 System for Fast NOx Measurement - This unique device enables measurement of NO and NO2 with an extremely high response time of 2 ms by locating the chemiluminescence detector in a remote sample head directly at the source. The sample gas is conveyed to the detector through heated capillaries, which minimizes sample gas mixing and yields a very fast response time. The CLD500 system includes two sample heads on tripods with 10 m conduits between the instrument cabinet and the sample point.

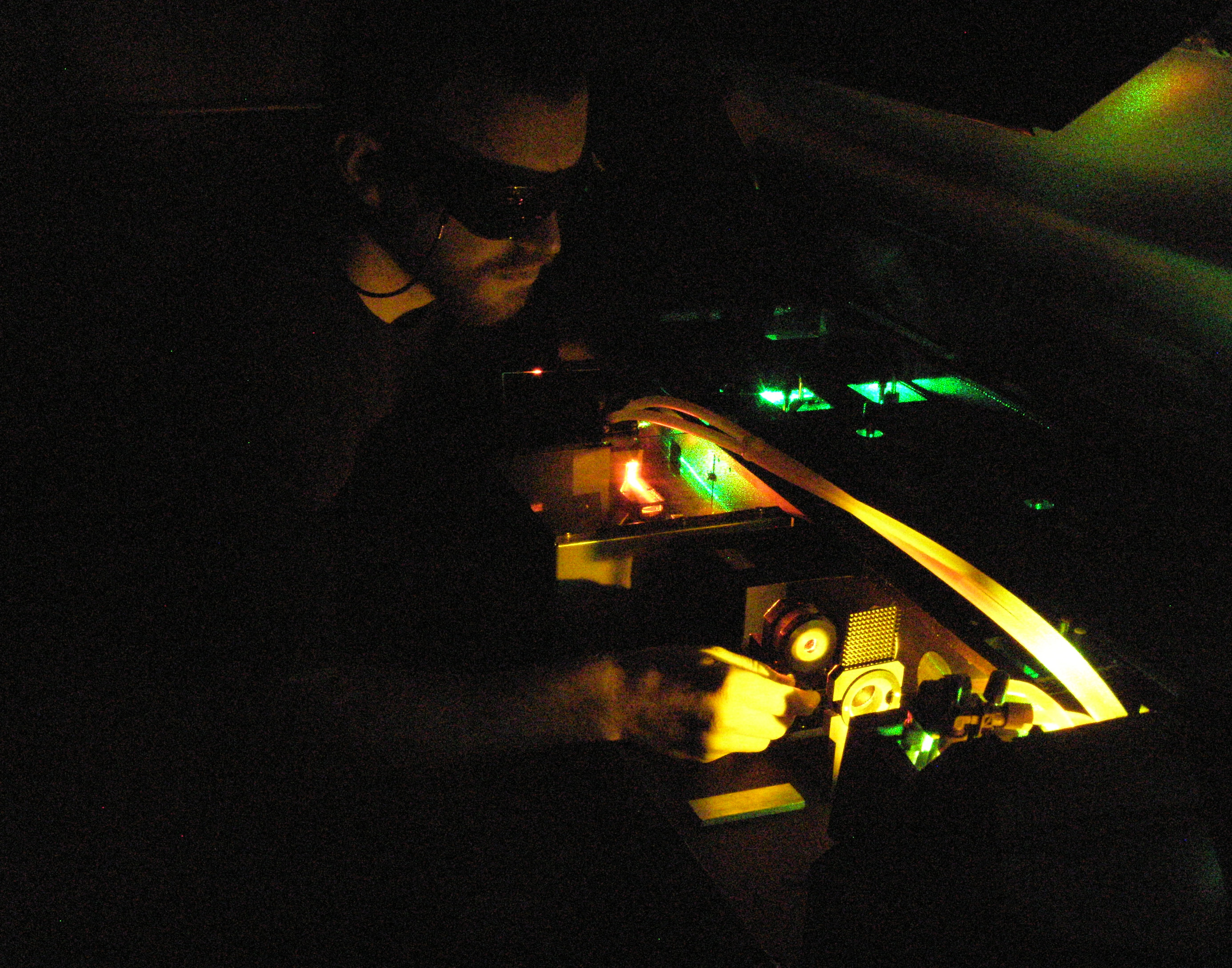

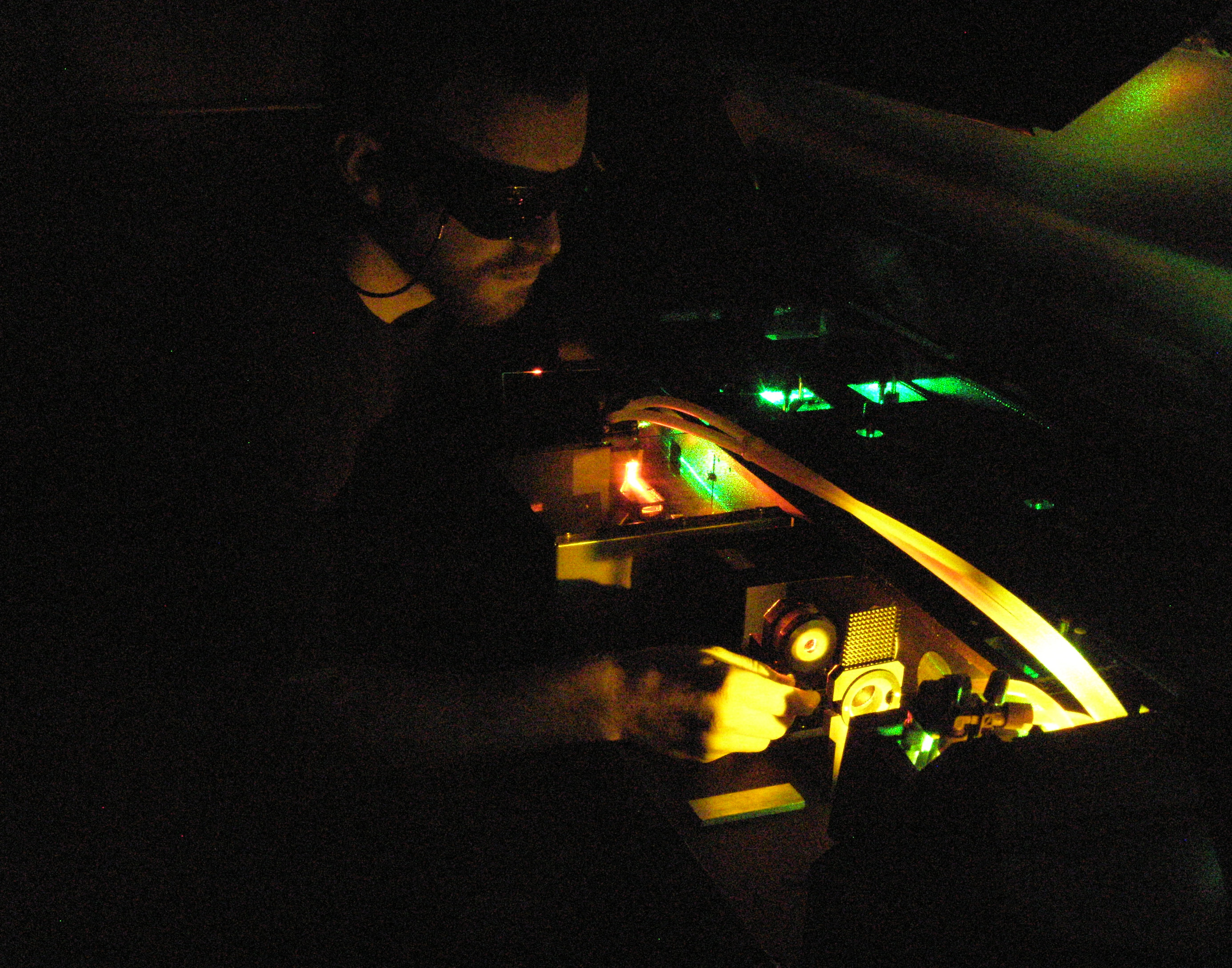

• Laser Diagnostics for Measurement of Trace Species in Chemically Reacting Systems - Resources include a SpectraPhysics Lab 150-10 Nd:YAG laser and Sirah Cobra-Stretch tunable dye laser with associated optical instrumentation necessary for planar laser induced fluorescence measurements of NO, OH, CH, CH2O and laser induced incandescence measurements of PM.

• Combustion Gas Analysis – Resources include a Nicolet Magna 560 FTIR and SRI 8610D Gas Chromatograph/FID

• Laminar Flame Burners - Quantitative measurements of radical species and stable intermediates in laminar flames are made using laser induced fluorescence. Capabilities for steady laminar flames include a premixed flat flame burner, opposed jet flat flame burner and 5-slot burner for steady two-dimensional edge flames.

• Vacuum Chamber for Low Pressure Flame Studies - Low-pressure, flat flame burner experiments are an effective means to measure trace species in flames using laser diagnostic techniques. By performing experiments at low pressures, it is possible to expand the thickness of the flame zone to roughly one centimeter in length, which facilitates the measurement of spatially varying concentration profiles of fuel, oxidizer, stable intermediates and radicals. The ABC2 laboratory is equipped with a vacuum chamber for low pressure flame studies. The system consists of a 13.25 inch vacuum chamber cube manufactured by MDC. The vacuum chamber has three 13.25 inch CF flange windows, one 13.25 inch door and multiple 2.5” CF flange feedthroughs. The system has a mechanical roughing pump and a Crytorr 8 vacuum pump that can be isolated from the chamber by a 13.25 inch vacuum gate valve manufactured by VAT.

3. Diesel Engines Available at the EECL

In addition to the fundamental combustion apparatuses described above, a series of diesel engines are available for emissions and performance studies:

• John Deere PowerTech Plus 4.5. - Tier 3, 4.5 liter, common rail fuel injector, 16 valve, turbocharged engine has a rated power of 173 hp at 2400 rpm. The engine utilizes approximately 10% EGR and has a variable geometry turbocharger. Current EPA Tier 3 emissions limits for diesel engines in the 100-175 hp range are 4 g/bkW-hr NOx and 0.3 g/bkW-hr PM.

• John Deere Model 6068H – Tier 2, 6 cylinder, common rail fuel injector, turbocharged, 6.8 liter engine rated at 275 HP at 2400 RPM.

• John Deere Model 4045H – Tier 2, 4 cylinder, common rail fuel injector, turbocharged, 4.5 liter engine rated at 175 HP at 2400 RPM. This engine is fitted with a fuel system that enables testing straight vegetable oil (SVO).

• John Deere Model 4024T / HCCI Engine – This 4 cylinder turbocharged, 2.4 liter engine, which is rated at 60 HP at 2800 RPM, has been modified to operate as a homogeneous charge compression ignition (HCCI) engine.

• Yanmar TF140E – single cylinder, 0.76 liter, direct injection diesel engine rated at 14 HP at 2400 RPM. This engine is suitable for long duration durability testing with specialty fuels.

4. Exhaust Gas Emission Measurement Capabilities at the EECL

• 5-gas emissions analysis: chemiluminescence measurement of NOx, flame ionization detection of hydrocarbons, paramagnetic detection of oxygen, non-dispersive infrared detection of CO and CO2

• Fourier Transform Infrared Analysis: speciated measurement of HC through C4, speciated measurement of NOx compounds (NO, NO2, N2O, N2O5, NH3, etc), SOx compounds, aldehydes (formaldehyde, acetaldehyde, acrolein).

• Gas Chromatograph analysis: for fuel analysis and exhaust hydrocarbon speciation

• Particulate Matter (PM) analysis: capabilities include total PM mass emissions, scanning mobility particle sizer (SMPS), elemental carbon/organic carbon analysis and aerosol mass spectrometer (AMS).

Last Updated:April 23, 2014